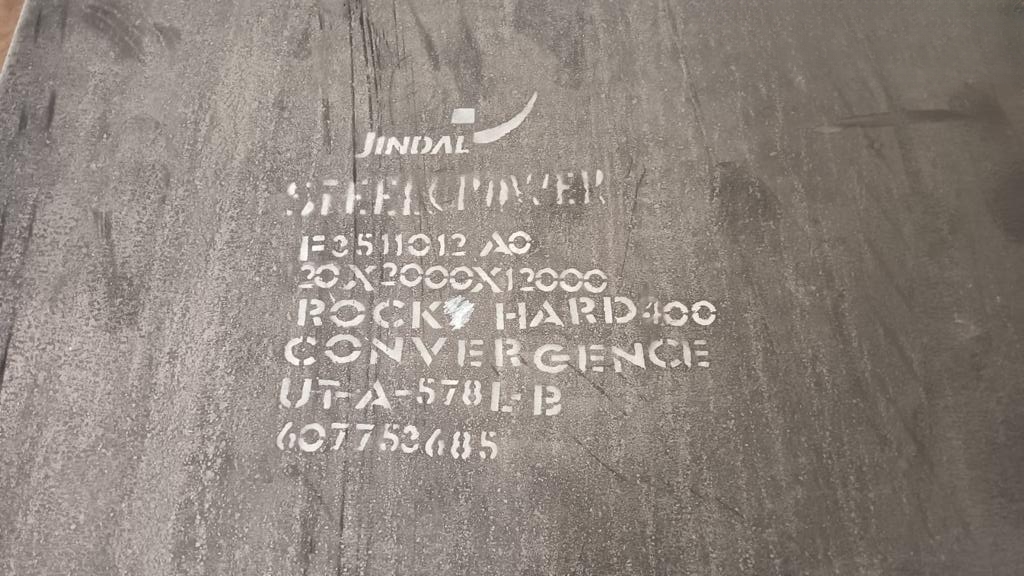

Rockhard 400 is a high-strength, abrasion-resistant steel plate manufactured by Jindal Steel & Power. Designed for applications involving high impact and wear, such as in mining, construction, and heavy-duty material handling, this quenched and tempered steel offers an ideal balance of hardness, toughness, and weldability. With a Brinell hardness range of 360–430 BHN, it provides extended service life even under harsh conditions. Rockhard 400 plates exhibit excellent mechanical strength, with yield strength around 1000 MPa and tensile strength up to 1250 MPa. They are available in thicknesses from 8 mm to 100 mm and are easy to cut, bend, and weld using standard fabrication practices. Its consistent quality, chemical composition, and dimensional tolerance make Rockhard 400 a reliable choice for industries seeking superior wear resistance and long-term performance.

Despite its high hardness, Rockhard 400 remains highly workable and fabrication-friendly. It supports common cutting and welding techniques, including manual arc, MIG/MAG, and submerged arc welding, with minimal preheating requirements for moderate thicknesses. Its relatively low carbon equivalent ensures good weldability,

while its predictable bending and forming characteristics make it suitable for a wide range of industrial designs. With dimensional accuracy, certified testing, and availability in a range of thicknesses and widths, Rockhard 400 offers a cost-effective solution for industries where abrasion resistance is critical to operational efficiency and component longevity.

What sets Rockhard 400 apart is its excellent combination of mechanical properties, including a minimum yield strength of around 1000 MPa, tensile strength of approximately 1250 MPa, and impact toughness of 27 Joules at -40°C, ensuring reliable performance even in extreme cold. The steel plate’s fabrication-friendly nature—enabled by a relatively low carbon equivalent (CE) and predictable cold forming behavior—allows it to be cut, welded, and bent using standard industrial techniques without the risk of compromising structural integrity. It is available in thicknesses ranging from 8 mm to 100 mm and in custom widths and lengths, making it highly adaptable to various project requirements. Commonly used in mining equipment, truck bodies, excavator buckets, liners, chutes, crushers, and construction machinery, Rockhard 400 significantly reduces downtime, maintenance cycles, and material replacement costs. By combining wear resistance with mechanical strength and processability, it serves as a cost-effective and long-lasting solution for industries seeking to extend the operational life of their equipment and optimize performance under heavy-duty working conditions.